Polyvalve Poly-Water® valves are everything you'd expect from the company that invented polyethylene valves.

Millions of Polyvalve Poly-Water® valves have been sold since 1976 and are in use throughout the world. Here's why:

| Item | Polyvalve II (C-style) | 2" through 12" |

|---|---|---|

| Body | Polyethylene | Polyethylene |

| Ball | Acetal | Polypropylene |

| Seat | EPDM | EPDM |

| Seat Retainer | Acetal | Polypropylene |

| Stem | Stainless Steel | Modified Phenylene Oxide |

| Stem Seal | EPDM | EPDM |

| Ground Water Seal | Neoprene | Neoprene |

| Adapter | Polypropylene | Polypropylene |

* Note: 12" has gear box and cast iron 2" square nut adaptor. 8" will have a choice of either gearing or wrench. Wrench adapter material is Acetal.

| SDR 9 | SDR 11 | SDR 13.5 | SDR 17 | |||||

|---|---|---|---|---|---|---|---|---|

| psig | bar | psig | bar | psig | bar | psig | bar | |

| PE 4710/3408 Material | ||||||||

| @74 °F | 200 | 13.8 | 160 | 11 | 128 | 8.8 | 100 | 6.9 |

| @23 °C | 200 | 13.8 | 160 | 11 | 128 | 8.8 | 100 | 6.9 |

| Resin Supplier | Material Description | Color | ASTM Material Designation | Material Density |

|---|---|---|---|---|

| Dow | DGDA 2490 | Black | PE 4710/3408 | High |

| Size (Inches) | Size (Metric) | Body Pieces | Port | End Configuration | Cv | Kv | Equivelant Feet of Pipe | Available SDRs |

|---|---|---|---|---|---|---|---|---|

| 1/2 | 16-20 | 2 | full† | BF or SF | 18 | 260 | 2 | 9.3 |

| 3/4 | 25 | 2 | full† | BF | 25 | 361 | 3.2 | 9.3, 10, 11 |

| 1 | 32 | 2 | standard† | BF | 40 | 577 | 3.8 | 9.3, 11, 13.5 |

| 1-1/4 | 40 | 2 | standard† | BF | 45 | 649 | 9.6 | 9.3, 11, 13.5 |

| 2 | 55-63 | 3 | full | BF | 175 | 2528 | 3.8 | 9.3, 11, 17 |

| 50-63 | 2 | standard† | BF | 110 | 1586 | 9.6 | 9.3, 11, 17 | |

| 3 | 90 | 3 | full | BF | 390 | 5624 | 5.3 | 9.3, 11, 13.5, 17 |

| 3 | standard | BF | 240 | 3461 | 14.1 | 9.3, 11, 13.5, 17 | ||

| 4 | 100-110 | 3 | full | BF | 700 | 10094 | 5.8 | 9.3, 11, 13.5, 17 |

| 3 | standard | BF | 400 | 5768 | 17.8 | 9.3, 11, 13.5, 17 | ||

| 6 | 150-160-180 | 3 | full | BF | 1800 | 25957 | 6.1 | 9.3, 11, 13.5, 17 |

| 125-160 | 3 | standard | BF | 900 | 12978 | 24.3 | 9.3, 11, 13.5, 17 | |

| 8 | 225 | 2 | full | BF | 3650 | 52633 | 5.5 | 11, 13.5, 17 |

| 3 | standard | BF | 1350 | 19467 | 40.3 | 9.3, 11, 13.5, 17 | ||

| 12 | 315 | 3 | full | BF | 7000 | 73542 | 10.6 | 11, 13.5, 17 |

Note: Cv in US gal/min @ 1 psi ΔP. Kv in litres/min @ 1 bar ΔP

BF for Butt Fusion, SF for Socket Fusion, † for Polyvalve II™ (C-Style) Valves

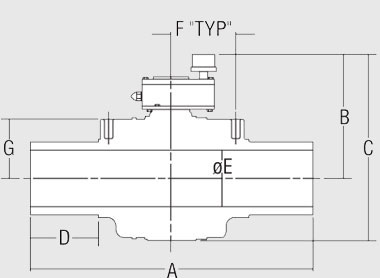

| Size | Port | A | B | C | D | E | Weight (lbs.) |

|---|---|---|---|---|---|---|---|

| 1/2 | full | 10.0 | 3.4 | 4.8 | 2.8 | 0.50 | 1.2 |

| 3/4 | full | 10.0 | 3.4 | 4.8 | 2.8 | 0.75 | 1.2 |

| 1 | standard | 10.0 | 3.4 | 4.8 | 2.8 | 0.90 | 1.2 |

| 1-1/4 | standard | 10.0 | 3.4 | 4.8 | 2.8 | 0.90 | 1.2 |

| 2 | full | 14.7 | 6.4 | 9.1 | 4.2 | 1.82 | 3.8 |

| standard | 13.0 | 4.5 | 6.5 | 3.7 | 1.30 | 3.1 | |

| 3 | full | 15.0 | 8.0 | 11.4 | 3.5 | 2.50 | 8.9 |

| standard | 12.8 | 6.4 | 9.1 | 3.6 | 1.90 | 4.5 | |

| 4 | full | 20.0 | 10.4 | 15.0 | 3.1 | 3.62 | 19.5 |

| standard | 15.0 | 8.0 | 11.4 | 3.8 | 2.50 | 8.9 | |

| 6 | full | 21.0 | 12.6 | 18.6 | 3.9 | 5.20 | 38.0 |

| standard | 20.0 | 10.4 | 15.0 | 5.3 | 3.62 | 23.0 | |

| 8 | full | 69.8 | 12.5 | 19.9 | 24.0 | 6.30 | 98.0 |

| standard | 20.0 | 12.6 | 18.6 | 4.0 | 4.78 | 42.5 | |

| Gear Operated | |||||||

| 8 | full | 69.8 | 14.8 | 22.2 | 24.0 | 6.30 | 134.0 |

| 12 | full | 83.8 | 17.5 | 27.7 | 30.0 | 9.91 | 305.0 |

*Optional vent holes. Contact factory for other vent options.

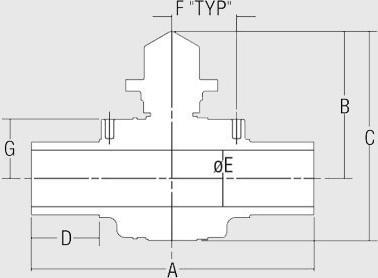

| Size | Port | A | B | C | D | E | Weight (lbs.) |

|---|---|---|---|---|---|---|---|

| 16-20 | full | 254 | 86 | 122 | 71 | 12.7 | 0.5 |

| 25 | full | 254 | 86 | 122 | 71 | 19.1 | 0.5 |

| 32 | standard | 254 | 86 | 122 | 71 | 22.9 | 0.5 |

| 40 | standard | 254 | 86 | 122 | 71 | 22.9 | 0.5 |

| 55-63 | full | 373 | 164 | 231 | 106 | 46.2 | 1.7 |

| 50-63 | standard | 330 | 115 | 165 | 94 | 33.0 | 1.4 |

| 90 | full | 381 | 203 | 290 | 89 | 63.5 | 4.0 |

| standard | 325 | 164 | 231 | 91 | 48.0 | 2.0 | |

| 100-110 | full | 508 | 264 | 381 | 77 | 91.9 | 8.8 |

| standard | 381 | 203 | 290 | 95 | 63.5 | 4.0 | |

| 150-160 & 180 | full | 533 | 320 | 472 | 99 | 132.1 | 17.2 |

| 125-160 | standard | 508 | 263 | 381 | 133 | 91.9 | 10.4 |

| 225 | full | 1773 | 318 | 504 | 610 | 160.0 | 44.5 |

| standard | 508 | 320 | 472 | 127 | 102.0 | 19.3 | |

| Gear Operated | |||||||

| 225 | full | 1773 | 363 | 561 | 610 | 160.0 | 60.8 |

| 315 | full | 2129 | 443 | 704 | 762 | 251.7 | 138.3 |

*Optional vent holes. Contact factory for other vent options.

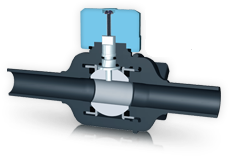

2"-12" Design

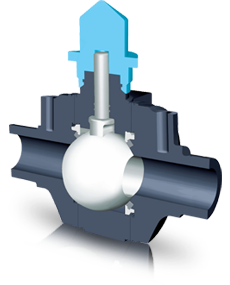

1/2"-2" Polyvalve II™ (C-style) Design

Note: Has high-strength stainless steel stem. 2" C-style is reduced bore only.